If you are planning to install insulation in your home, the two most popular options you have are cellulose (sometimes called blown-in) and spray foam insulation. While both of them have their pros and cons, you will have to evaluate the requirements or circumstances of your home to make the right decision.

Types of Insulation

Let’s have a look at both types of insulations and compare them based on their most important characteristics.

Spray Foam Insulation

In spray foam insulation, you blow-in or spray polyurethane foam into the ceilings, walls, and other areas of your home where insulation is required. The material expands upon application, effectively air sealing the area. It dissipates heat outside your house during the hotter seasons and keeps it inside during the colder seasons. Spray foam insulation is pest resistant and waterproof (closed cell) as well.

Cellulose Insulation

This type of insulation is made using recycled newsprint fibers that are treated using non-toxic borate. Cellulose insulation is resistant to fire, mold, and pests, and can be installed over other materials. It is ideal for filling different enclosed spaces such as wall cavities and attic floors.

Comparison between Cellulose Insulation and Spray Foam Insulation

Cost and Lifespan

Spray foam insulation costs about 50%-75% more than cellulose insulation. Both insulation types last many years.

Material hazard

Since cellulose is made from recycled, organic materials (newspaper), it is considered to be among the safest materials for home insulation and considered green. Due to its non-toxic nature, accidental exposure to cellulose doesn’t cause any harm during and after installation.

Spray foam can easily catch fire as it is flammable and produces a lot of smoke. However, you can overcome this drawback by installing a fire or thermal resistant barrier after its installation.

Moisture Absorption

Since spray foam is either water resistant (open-cell) or waterproof (closed cell), it has benefits and disadvantages depending on the application. Cellulose Insulation “wicks” water through itself and therefore the water naturally evaporates. If you put a drop of water on a piece of paper, the paper will absorb the water and that initial drop will spread around the initial drop until the water evaporates. The same process happens when a water leak comes into contact with cellulose.

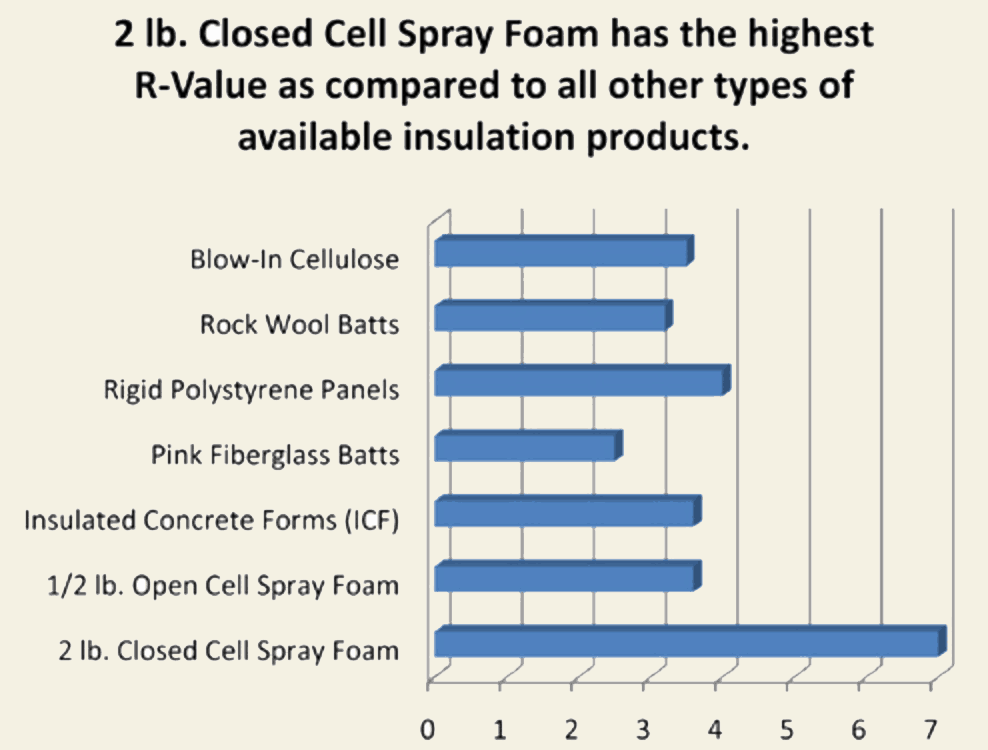

R-Value Spray Foam

R-Value Spray foam insulation, the more costly alternative, can be higher performing when the closed-cell version is used. Spray foam has two main versions; open-cell which has an R-value of 3.2 per inch and closed cell which has an R-value of 6 per inch. Cellulose insulation has an R-value of 3.5 per inch but is much more affordable. Regarding r-value, there is a tie between both the insulation materials. The R-value of cellulose is 3.6-3.8 per inch, while for spray foam, it is 3.5-3.7.

Generally speaking, NEEECO recommends cellulose insulation over spray foam insulation for retrofit construction (existing homes). In Massachusetts, the Mass Save® program subsidizes air sealing and insulation upgrades to existing homes. Air sealing is installed at no cost to homeowners who have a National Grid or Eversource utility account. Insulation is heavily subsidized with a rebate of up to $2000 (75% off the work up to $2000).

For new construction, NEEECO recommends spray foam since the home is wide open and the spray foam installation is very quick. There are no rebates available for spray foam.

However, we recommend that you talk to an expert insulation and energy auditing company like NEEECO to get professional advice regarding the best type of insulation for your home.

Call (781) 514-5882 or contact us to get started with a no-cost Mass Save® home energy assessment.

Thank you for the awesome content. I have shared it on my facebook

page.